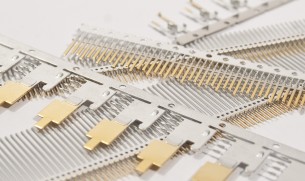

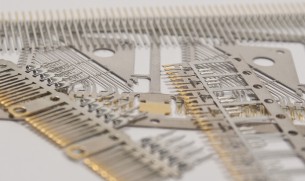

Penn United Technologies’ plating department understands the importance of quality, perseverance, precision, and customer confidentiality. We work hand in hand with a wide range of companies and stamping houses to plate their products. We are willing to work hard not only to gain your trust—but to keep it.

Our plating department offers reel-to-reel precision plating services to both customers and our in-house metal stamped products. We are dedicated to providing the highest quality product, on-time delivery, and lower production costs through the use of advanced technology, chemistry, and testing.

We provide:

Processes/finishes |

Process techniques |

|

|

Penn United’s reel-to-reel plating services can also be combined with our other in-house capabilities, such as metal stamping and product assembly to provide you with a complete range of manufacturing solutions.

Contact us today for more information or to request a quote.

Headquarters

799 North Pike Road

Cabot PA, 16023

tel: 724-352-1507

fax: 724-352-4970

© 2022 Penn United Technologies, Inc. All Rights Reserved.