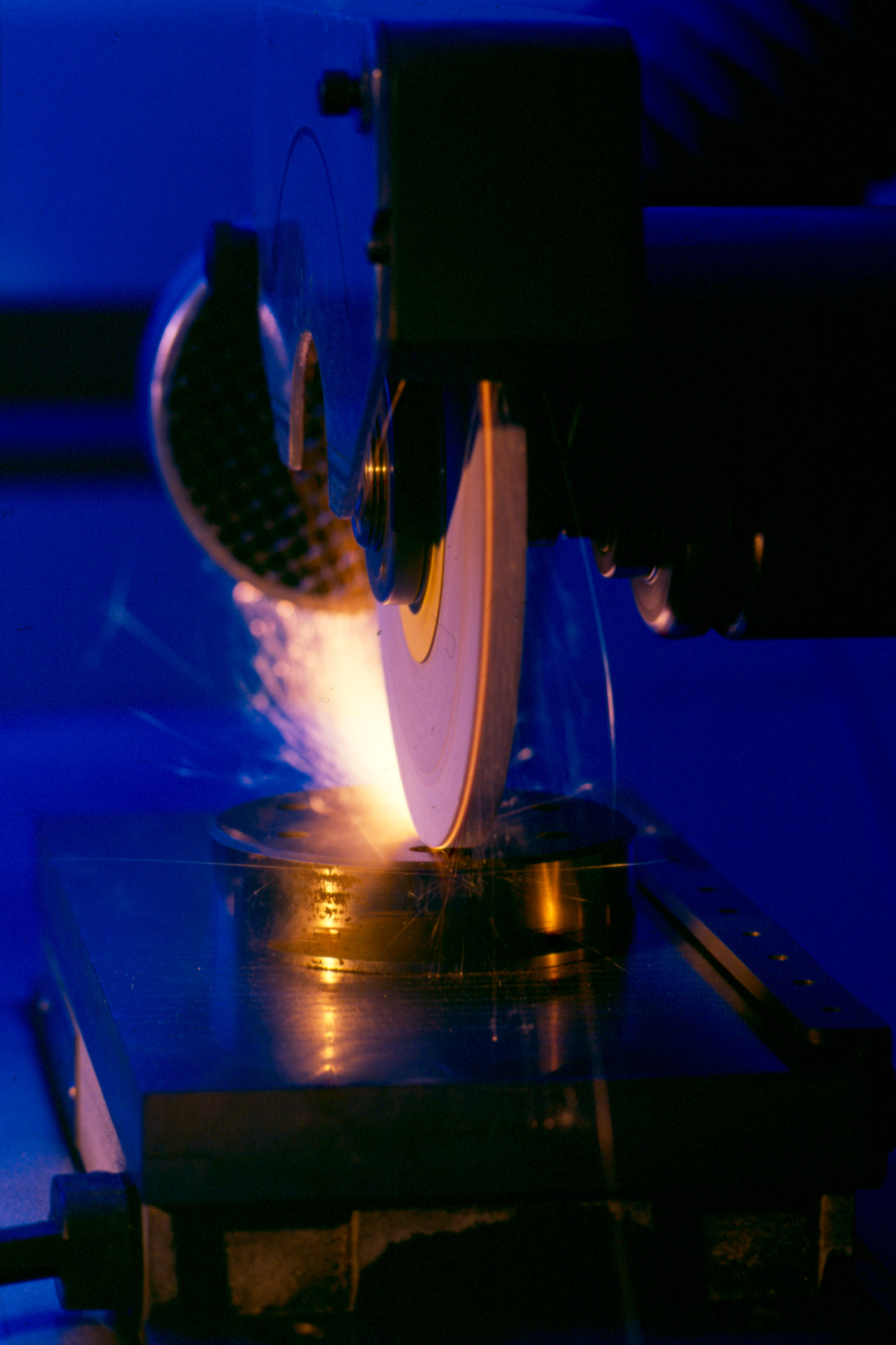

Custom and Production Machining

Penn United’s Precision Machining Group specializes in high precision metal machining for critical-application components. By offering the highest quality in precision machining capabilities, we stand ready to become your premier source for challenging machining jobs.

Common materials machined:

- Aluminum

- Copper

- Brass

- Ceramic

- Inconel® alloys

- Nickel alloys

- Duplex alloys

- MP35N

- Powdered metal

- Tool steels

- Stainless steel

- Titanium

- Tungsten carbide

Common components machined:

- Blowout preventers (control system components)

- Manifolds

- Valve components

- Valve bodies

- Stab components

- Choke components

- Hydraulic regulators

- Pump/compressor components

- Gage components

- Firearm components

- Die and die components

- Others

Milling-Turning

- Small, medium or large lot sizes

- Single set-up, 10-axis CNC Mill-Turn Centers available

- Specializing in Critical Components with demanding features and critical tolerances

- Valve components

- Small turbine components

- Control components

- Pump and compressor components

- First article inspections, CMM Capabilities, inspection reports